Printer Status LED’s

The Epic 880TM printer has four indicator lights to indicate various operating states of the printer. In general these are Fault, Cover Open, Paper Status, and Ready.

The printer may be in normal operation, self test or in one of two boot load modes. The Ready and Fault indicators will indicate which mode by a unique blink pattern:

TransAct Boot Load Mode

In TransAct Boot Load Mode, the power LED will blink slowly with a 50% duty cycle. It will repeat this cycle about every 2 seconds (1 Sec on, 1 Sec off). There will be a red indication on the Error LED indicator until the down load is started.

Self Test Mode

When the printer is in Self Test Mode, the power indicator will blink slowly with a 50% duty cycle at a 2 second rate. This is very similar to TransAct Boot Load Mode, however, the red error indicator will not be present.

Normal Operation

During Normal operation, the Power LED will remain on unless an error is being indicated. There are two classes of errors, soft errors and hard errors. Soft errors are recoverable without power cycling the printer; conversely, recovering from hard errors requires removing the power from the printer, correcting the problem, and then reapplying power.

| Status | LED response |

| Power On, Printer Ready | Ready LED on (Not Blinking) |

| Paper Low | Paper LED Blinking |

Soft Errors

Soft errors may be recovered by the host, or by opening and closing the printer cover. Each of these errors is indicated by a 5 second repeating blink pattern on the Power LED with the red Fault LED continuously on.

| Out of Paper | 2 blinks | Paper LED will also be on |

| Cover Open | 4 blinks | |

| Jam Detected | 5 blinks | |

| Missed Top of Form | 6 blinks | Paper LED will blink fast |

| Illegal or Bad Command | 7 blinks | Paper LED will blink fast |

| Printer Over Temp | 8 blinks | Fault LED will blink slow |

| Bad Power | 8 blinks | Fault LED will blink fast |

Hard Errors

Hard errors have a similar blink pattern to soft errors, except that they are slower and repeat every 10 seconds. In general, these errors occur during level 0 diagnostics and are not recoverable. In these cases, the Error and Power LEDs will blink at the same time.

Auto Error Recovery

The Epic 880TM printer has the ability to auto recover from some internal errors.

Flash Format Errors

The internal flash that is used to store graphic images is formatted to assure data integrity. If this format is corrupted, the printer will automatically delete and reformat the flash. The host can then reload the images.

Input Power Fault

The printer monitors the power input to the printer. If it is found to be greater than 26 volts or less than 20, the printer will stop and wait for the power to return to specification.

Head Temperature Fault

The printer monitors the head temperature. If the head temperature is greater than 60º C, the printer will start to slow down. If the head exceeds 65º C, the printer will stop. The printer will heat the head to maintain a head temperature of 25º C. If the printer cannot maintain a head temperature of 0º C, the printer will stop. In all cases, the printer will automatically recover when the head temperature is within range.

Configuration Fault Recovery

The printer maintains an operating configuration in EEPROM. Information such as the printer’s serial number, operating configuration, and running totals are stored in this memory. Each section of this memory maintains a check character to signal that the data is valid. If this memory is found to be corrupted, the printer will restore it based on a backup copy saved in flash. This flash copy is generated when the printer was electronically configured using the TransAct® configuration tool. Any configuration parameters altered during normal operation will not be saved in the flash copy. The EEPROM will be restored to the value set by the configuration program.

Cleaning the Print Head

Once the unit is opened, the paper path is accessible for cleaning or clearing paper. Use a soft brush to clean the paper dust from inside the printer. The paper dust should also be removed from the sensor optics. If streaking on the printed ticket is evident, the thermal print head may need to be cleaned. This can be with a cotton swab moistened with an alcohol solvent (ethanol, methanol, IPA).

Warning: After printing, the print head can be very hot. Be careful not to touch it and let it cool down before you clean it. Do not damage the print head by touching it with your fingers or any hard object.

Printer Sensors

The Epic 880TM printer uses several sensors to provide feedback to the host system, as pictured in the figures below.

Paper Out Sensor

A Paper Out Sensor, mounted to the Lower Paper Guide, optically senses a Paper Out flag located in the ticket path. When the sensor detects the flag, it indicates that the ticket roll is depleted.

Cover-Open Switch

A Cover-Open Switch, mounted to the inner left side plate, is activated when the Top Cover is closed and the latch depresses the switch arm. When the Top Cover is opened, the Cover Open switch trips, and the printer goes off-line.

Top-of-Form Sensor

A Top-of-Form Sensor is mounted in the paper path, and senses a pre-printed black dot (if present) on the ticket stock. This black mark is used to position the paper for printing on a preprinted form. Typically the ticket is pre-positioned to the Top-of-Form and when the ticket is complete, the paper is fed to the Top-of-Form and then cut.

Paper Low Sensor

The Epic 880TM has a Paper Low Sensor. This sensor is mounted to the paper spindle and will provide an indication that the paper is getting low. The length of paper remaining when paper low is sensed is dependent on the paper roll core diameter.

Anti-Jam Sensor

An Anti-Jam Sensor is mounted to the knife frame, and senses the presence of a ticket immediately before and after a knife cut. Under normal conditions, right after a knife cut, a ticket is fed into the transport and presented to the customer. If a ticket is not fed properly into the transport (for example, when a ticket jams) the Anti-Jam Sensor detects the jammed ticket and stops printer operation.

Transport Ticket Taken Sensor

A Ticket Taken Sensor, mounted in the Ticket Transport, is used to detect the lead edge of the ticket as well as determine when customers have actually taken the printed ticket.

Transport Ticket Retract Sensor

The Ticket Retract Sensor, mounted in the Ticket Transport retract path, is used to detect the presence of the ticket in the retract path. Under normal operation, the retract path should be clear after the retract.

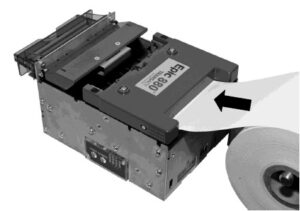

Loading Paper

The Epic 880 printer uses a continuous roll of POS or Lottery grade thermal paper, with specifications outlined in the chapter Epic 880TM Specifications and Requirements.

Instructions for auto-feeding the paper are as follows:

- Place a roll of new paper on the spindle, with the end of the paper unloading from the back to the front of the printer, as shown in the figure.

- Thread the free end of the paper under the top cover as shown.

- Push the end of the paper forward until it engages the Paper Out sensor, located under the center of the top cover.

- Paper will feed automatically, and then print and eject a test ticket.