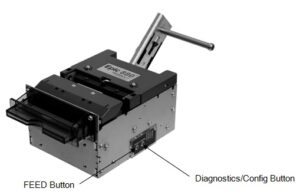

The Diagnostics/Config button

The printer has a configuration and diagnostics button on the right side of the printer, labeled CONFIG.

The Diagnostics/Config button is a multifunction button. By pressing and releasing the Diagnostics/Config button, the printer will enter self test mode. This is intended to verify the printer’s operation.

By pressing and holding the Diagnostics/Config button for a longer time, two additional features may be activated. Pressing and holding the button for about two seconds will enter hex dump mode. Holding the button for about 4 seconds will enter configuration mode.

To aid in selecting the correct mode, the Fault LED will illuminate as soon as the button is pressed and indicates that self test is selected. After about 2 seconds the Fault LED will go out and the PAPER indicator will illuminate. This indicates that hex-dump mode is selected. After about 4 seconds, the Cover LED will illuminate indicating configuration mode is selected

Using Self-Test

Self-Test Mode allows you to perform a series of tests to show if the printer is functioning correctly.

To enter self test, momentarily press[1] the Diagnostics/Config button on the side of the printer.

The Epic 880TM has several Self-Test options. Some are designed to be useful when performing on-site print evaluations. Others are designed for factory setup by TransAct.

Once in test mode, the FEED button is used to select the test to be run.

Testing the printer

Use the first three TEST options when verifying basic printer operation. The last three options are for factory test.

Operation –Ticket Print

The receipt test is the primary test option to use when determining if the printer is functioning correctly.

The ticket test is mostly used during the early stages of troubleshooting, to eliminate the possibility that the problem is occurring with the printer. If the printer experiences a failure, and the error indicator light is activated, call TransAct’s Technical Support department.

Operation – Head Test

This test performs a test pattern that will print all the head print elements and verify that the drive roll is free from defects or debris. The print head has two heating elements per dot position. A print element is not considered bad unless both elements are missing. If the head test shows that there is an inconsistency in the print there may be debris on the drive roll. If debris is indicated, cleaning the drive roll should correct the problem. If this does not correct the problem, contact TransAct’s Technical Support department.

Operation – Marker Calibration

The printer is equipped with several sensors in the paper path, which are adjustable and will handle a wide range of paper under normal operation. However, if there appear to be problems associated with any sensor’s operation, the Marker Calibration test will attempt to adjust the sensors for optional operation with the paper installed. The Top-of-Form, Paper Out and Jam sensors will be recalibrated. To run this test, simply select it. The printer will automatically position the paper and adjust the sensors. If the paper installed does not have black dot markings, the Top-of-Form sensor will be adjusted based on the white level of the paper only.

Factory Test

The printer is equipped with several factory test modes. These test options are only used for factory burn-in and testing.

Operation – Continuous

Operation – Burn-in

Operation – Rolling ASCII